Empower Technology

Higher performance for the semiconductor and electronics industry

The HEIDENHAIN GROUP is your partner for solutions

combining precision, dynamic performance, practical value, and reliability.

Join us in breaking the accuracy barrier.

Discover our pioneering innovations

that unlock the N+1 process node.

NEPCON 2026 Tokyo/Japan: January 21 to 23, 2026 | SEMICON Seoul/Korea: February 11 - 13, 2026

Advanced Packaging

Discover higher accuracy and productivity: MULTI-DOF TECHNOLOGY from HEIDENHAIN and the latest stage from ETEL, the TELICA HP, featuring ACCURET+ position control and the QUIET active isolation system, are unlocking new dimensions for hybrid bonding, thermocompression bonding, and fan-out applications.

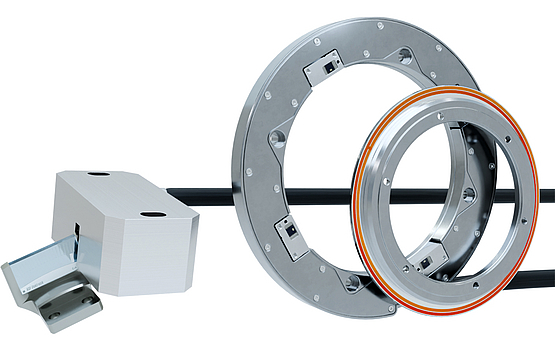

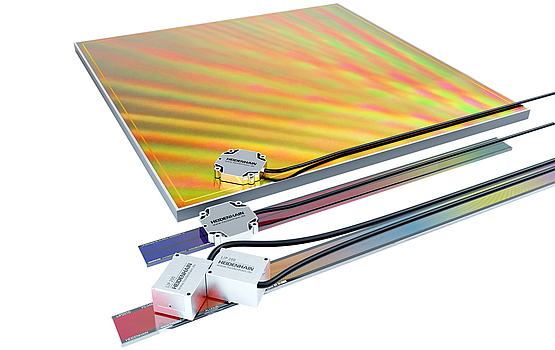

High-end Automation

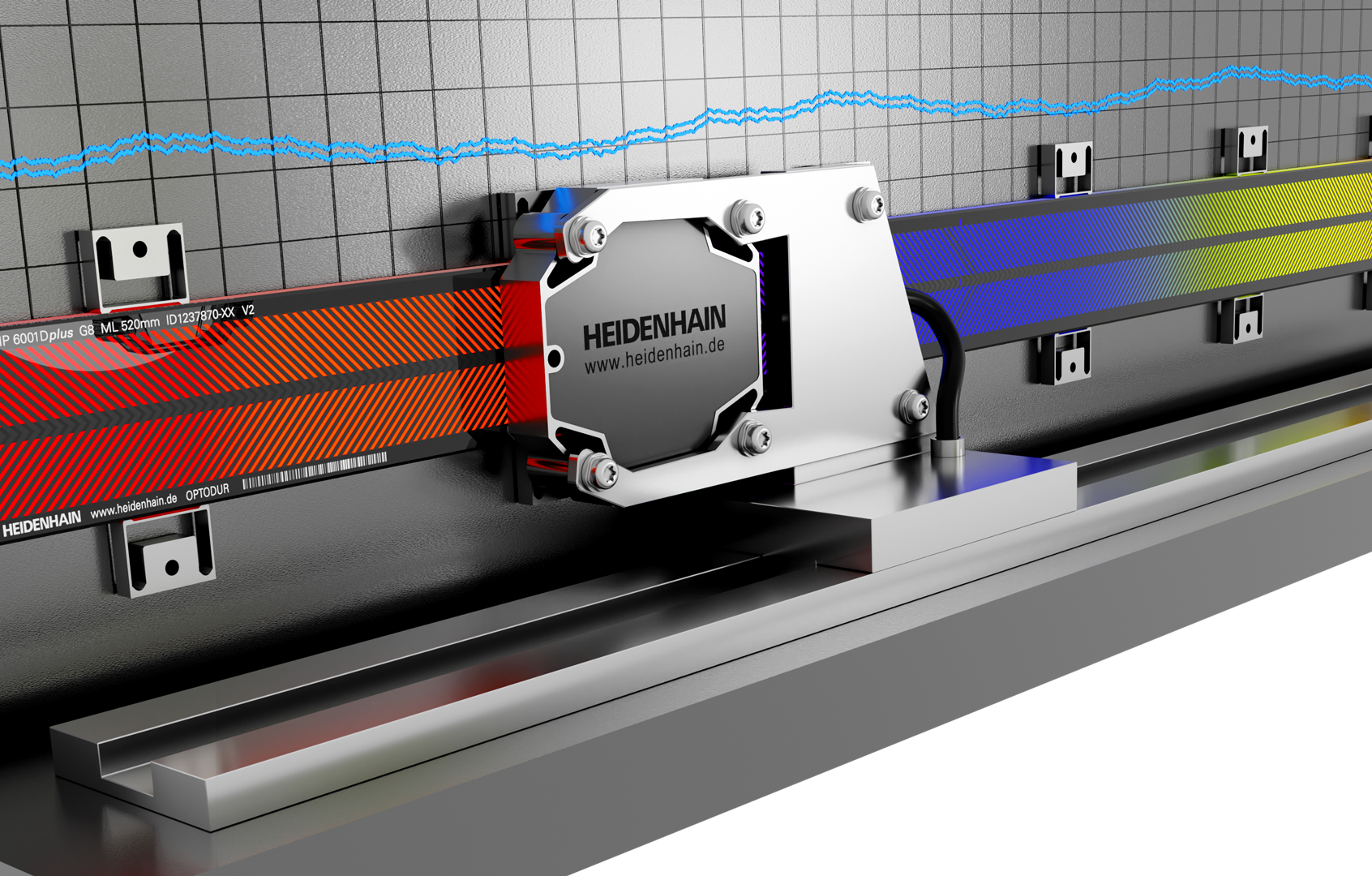

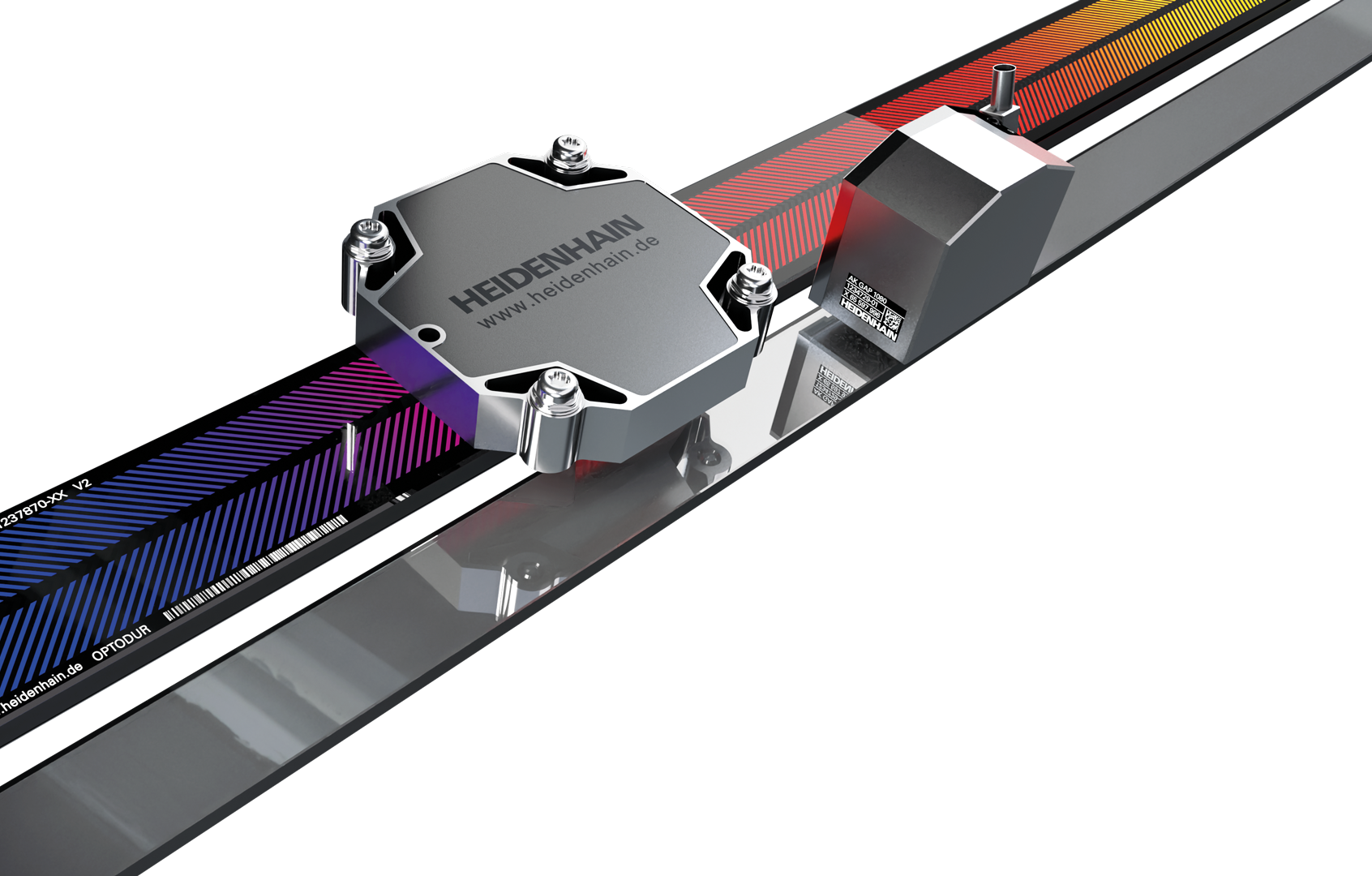

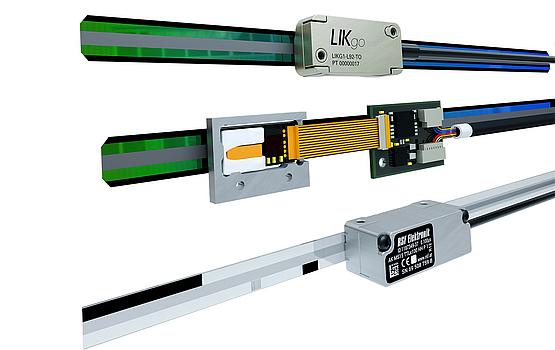

Unleash dynamic performance and accuracy for axis positioning in laser applications with galvo scanners and more. Encoders from HEIDENHAIN, NUMERIK JENA, and RSF, as well as motion systems from ETEL, offer versatile solutions for every application, including applications with very limited installation space.

Back-end Assembly

Accelerate your production and inspection processes: The HEIDENHAIN GROUP offers optimal solutions for high-performance wire bonding and die bonding processes, providing linear and angle encoders from HEIDENHAIN, NUMERIK JENA, and RSF, as well as handling solutions from ETEL.

Metrology & Inspection

High-accuracy processes require machines with high-precision motion at the tool center point. We offer tools for determining the accuracy of your machines, allowing you to inspect and recalibrate them. Ensure optimal results by compensating for thermal drift and Abbé errors.

WINGLET Software

How can you easily optimize highly complex motion systems? With the WINGLET software developed by ETEL. Whether during initial setup or for testing and readjustment when used in facilities for the production of semiconductors and electronic components, it ensures a perfect system setup for maximum performance.

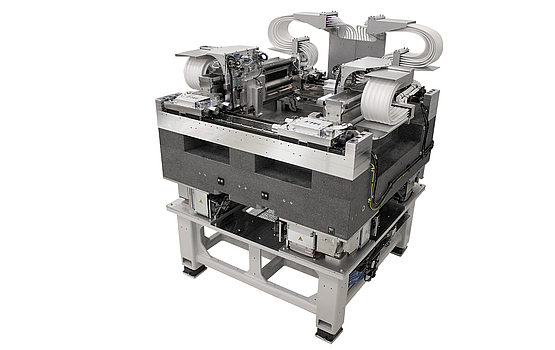

CHARON2 HD and Z3TM+

Greater productivity and a higher degree of accuracy are made possible by the interplay of the highly dynamic CHARON2 HD motion system and the Z3TM+ module. This combination delivers motion control in six degrees of freedom and a special lifting mechanism for easier wafer handling.