Virtual show

|

SEMICONDUCTORS & ELECTRONICS

Empower Technology

Higher performance for the semiconductor and electronics industry

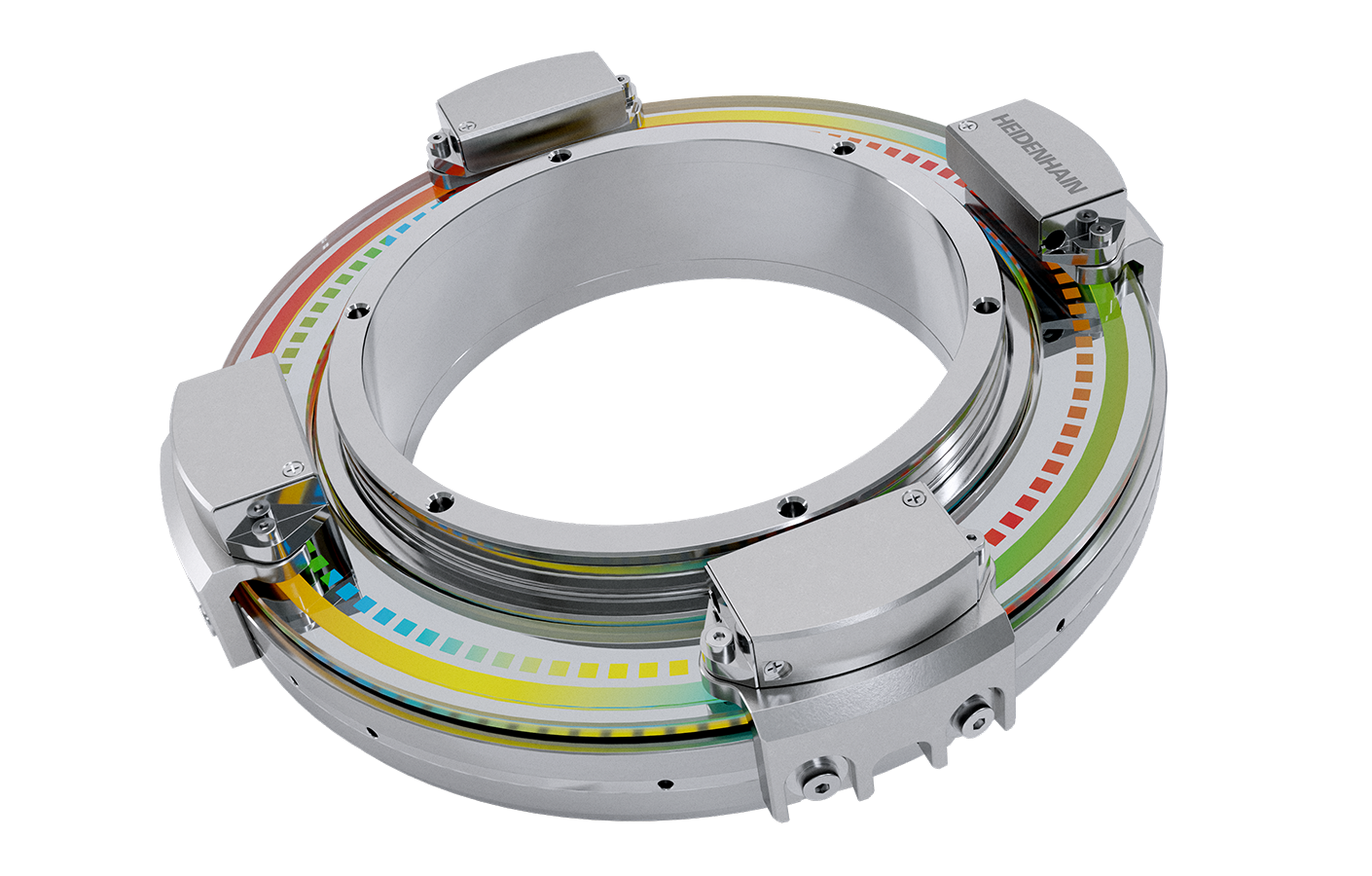

The HEIDENHAIN GROUP is your partner for solutions

combining precision, dynamic performance, practical value, and reliability.

Join us in breaking the accuracy barrier.

Discover our pioneering innovations

that unlock the N+1 process node.

NEPCON 2026 Tokyo/Japan: January 21 to 23, 2026 | SEMICON Seoul/Korea: February 11 - 13, 2026